5 Important Considerations when Dealing with Control Valves

1. Flow Conditions inside a Control Valve

2. Difference in Flowing Conditions between Liquids and Gasses

When dealing with a liquid, the velocity of the fluid through a control valve will increase, as the cross-sectional area of the throat area of the control valve decreases. When dealing with gases, a totally different response comes into play. It is essential that you understand these variations in full.

3. Classification of Control Valves

Most people would classify a control valve according to its operation, which would be based on the movement of the actuator. Then, there would be the classification by means of functionality, which is related more to the type of control that is implemented. But, there is a further classification, and this would be specific to the actual application. This is particularly useful, when considering certain services.

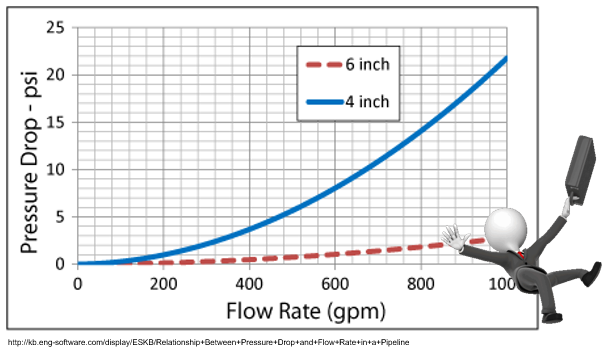

4. Relationship between Pressure and Flow

5. Cavitation

When does cavitation cause the most damage? Would it be at the start or the end of the cavitation process? What are the solutions to cavitation? Could something be done to the valve? Could something be done to the process? What about upstream and downstream considerations? Cavitation has the potential to do a lot of damage, and must be dealt with effectively.

These five aspects only pertain to the control valves. What about the actuators? To get these answers, and many other skill-sets pertaining to valves and actuators, you should not hesitate in enlisting for PetroKnowledge’s Control Valves and Actuators training course, to get all the correct information directly from a specialist. This training has been scheduled to run in multiple venues, and you would be advised to keep a very close eye on the Petroknowledge calendar.